Contact us

Address: 8633 East Mizhou Road , Zhucheng city , Shandong Province,China

Fax:0086-536-6053915

Tel:0086-536-6053990

Tel:0086-187-66363705(Jerry Jiang)

Email:tyjx@tyjxchina.com

When peeling potatoes, carrots, fruits and other root vegetables, mechanical peeling methods such as cutting peeling or friction peeling will cause up to 5 0% peeling loss, and the peel and flesh on the vegetable surface will be greatly removed at the same time. Steam peeling can help customers greatly reduce the peeling loss, increase the yield, and increase profits by reducing the loss of raw materials. Steam peeling line can ensure stable and efficient peeling, even if the needle is of uneven quality, it can also achieve a very good peeling effect and yield.

The automatic technology of steam peeling process can realize the intelligent control of the whole peeling process. The sensor-based technology can real-time monitor the equipment and peeling effect, and timely feedback to the control system for adjustment to ensure short steam duration of zui and low peeling loss of zui. With an intuitive and easy-to-use interface, operators can easily check and adjust production. Dute's real-time monitoring and feedback system can ensure that customers with different needs can achieve zui efficiency.

Scope of application:

This machine is an imported steam physical peeling equipment, which is widely used in carrots, sweet potatoes, potatoes, tomatoes, persimmons and other food industries.

Main technical parameters:

Processing capacity: 3-20 t / h (tomatoes).

How it works:

The plate hoist sends the batch material into the feed star valve, and the scraper of the feed star valve enters the material into the spiral pressure chamber, and the material is transported by screw to the discharge end. During the material propulsion process, the steam of 5~10bar is sprayed on the material in the pressure chamber. It usually takes 30 to 60 seconds to scald the material and the pulp depth is 1-2mm thickness. At this time, the skin of the material has been scalded (then the skin of tomato or persimmon is cracked and the pulp is completely delaminated), and the discharge is controlled by a star valve.After that, the material is discharged into the cold water tank and delaminated with cold water, and the scalded surface will be removed by rubber hexagonal roller brush equipment.

Features:

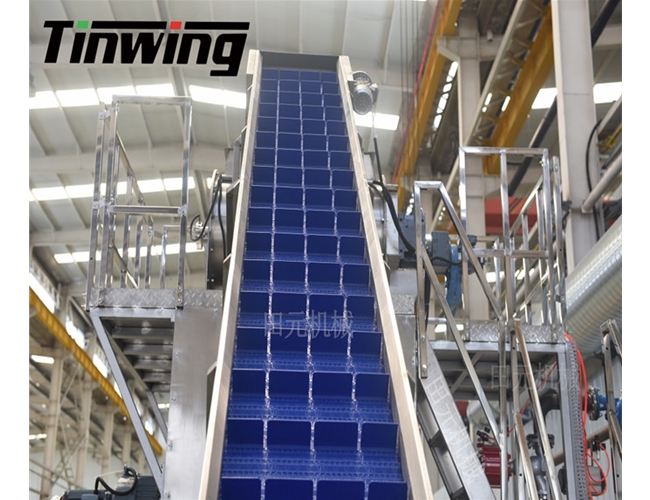

Plate lifting can be used to realize feeding (mechanical speed regulation).

The bottom of the tank is provided with a sewage discharge valve and a steam recoil device.

The cymbal star valve realizes in and out of the material.

The material is driven by a screw conveyor in the cylindrical fuselage, in which the steam pressure is 4-5bar (low pressure), and the residence time of the material in it is adjusted mechanically.

The whole process can be produced continuously, and it has the characteristics of high efficiency, high peeling rate and low material loss rate.

It is made of all sus304 stainless steel sandblasting or polishing, which meets the requirements of food hygiene standards and food machinery safety and hygiene standards.